Yokohama India - Other Tyre Construction

Yokohama India - Other Tyre Construction

Other Tyre Construction

Tyres can be classified according to the arrangement of the cord layer, into the radial tyre and bias tyre (cross-ply tyre). But most of the tyres used at present are radial tyres thanks to their proper advantages. Tyres can also be classified according to the method of retaining inflation pressure, into the tubeless tyres and tube-type tyres, but most vehicles currently adopt tubeless method.

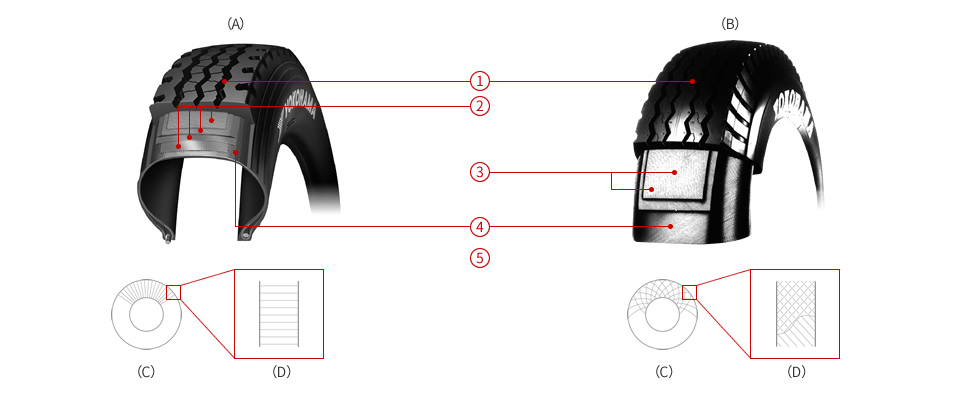

Radial Tyre and Bias Tyre

- Structure of the radial tyre

- The cords forming the carcass are arranged perpendicularly to the centre line of the tread or in a radial direction from the centre of the circle.

- Structure of the bias tyre (cross-ply tyre)

- The cords forming the carcass are intersected at a diagonal (biased) angle of about 40° with respect to the tread centre line.

- (A) Radial tyre

- (B) Bias tyre

- (C) Side view

- (D) Front view

- Tread

- Belt

- Breaker

- Carcass

- Arrangement of carcass cords

Advantages of the radial tyre

- 1. High-speed durability.

- 2. Low heat generation.

- 3. Low rolling resistance, contributing to fuel saving.

- 4. Better wear resistance.

- 5. Excellent cornering ability and stability.

- 6. Less slipping and high traction force.

Radial Tyre and Bias Tyre

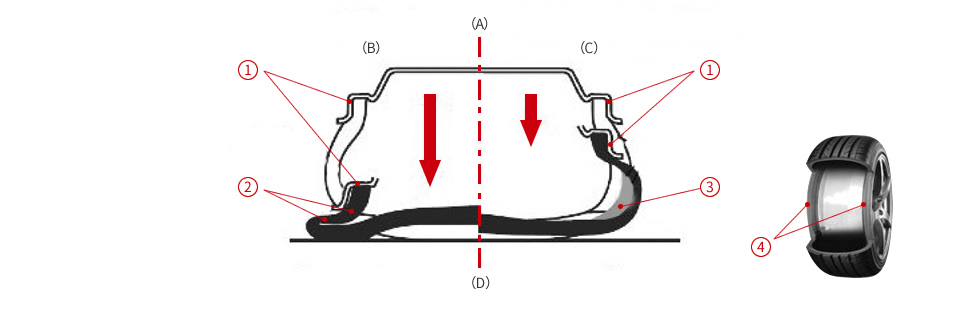

The tubeless tyre does not use a tube. Instead, it maintains inflation pressure in the tyre by the attachment of a special rubber liner called the “inner liner,” that features low air permeability on the internal surface of the tyre. While the valve of a tube-type tyre is attached to the tube that of the tubeless tyre is a special valve attached directly to the rim.

- (A) Cross sections of a tubeless tyre and a tube type tyre

- (B) Tubeless tyre

- (C) Tube-type tyre

- (D) Advantages of the tubeless tyre

- Innner liner

- Tubeless valve

- Tube

- Flap

- Tube valve

- Tyre

- Wheel

- Side/Lock ring

- 1. The absence of a tube has eliminated the problems that were formerly related to the tube.

- 2. Air does not leak suddenly even if the tyre is pierced by a nail or other sharp object, thereby contributing to the prevention of accidents resulting from tyre damage.

- 3. Air is in direct contact with the rim, thereby improving the heat dissipation.

- 4. Helps to decrease the tire weight, reduces its cost and enables easier tire maintenance.

Cautions

- 1. Special care is required when assembling the rim because damage to the bead tends to promote air leaks.

- 2. Check the rim and valve for damage and deformation periodically, as these may be a cause of air leaks.

- 3. Although a tubeless tire is not susceptible to sudden and rapid air leaks, a driver tends not to notice any drop in the tyre’s internal air pressure. This makes it necessary to check the tyre, wheel and inflation pressure periodically.

Runflat tyre

The runflat tyre is designed for use as a standard tyre that does not need to be supported by a spare tyre. The sidewalls are reinforced with rubber so that, even in the case of a puncture, the tyre can continue running for a while.

- (A) Cross-section of runflat type tyre

- (B) Ordinary tyre

- (C) Self supporting runflat tyre

- (D) Cross-section of a tire at zero pressure (Image)

- Wfeel rim

- Sidewall

- Reinforced sidewall

- Self supporting reinforcement

* With run flat tyres it is not easy to identify any decrease in pressure, even if this is due to a puncture. For this reason, in the case of runflat tyres installed it is necessary to mount an inflation pressure alarm unit in order to detect any air leakage.